- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Step-by-Step Guide: How to Add Natural Vitamin E Powder to Poultry Feed

Adding Natural Vitamin E Powder for Feed to poultry nutrition programs requires a systematic approach that balances optimal dosing with practical implementation. Natural vitamin E, primarily d-alpha tocopherol, delivers superior bioavailability compared to synthetic alternatives, making it an essential component for modern poultry operations. This comprehensive guide provides feed formulators and procurement professionals with the essential steps to successfully incorporate natural vitamin E into their poultry feed systems while maximizing both efficacy and cost-effectiveness.

Understanding Natural Vitamin E Powder and Its Role in Poultry Nutrition

Natural vitamin E powder represents a critical advancement in poultry feed supplementation, offering distinct advantages over conventional synthetic forms. The FDA has established that natural vitamin E demonstrates approximately twice the bioavailability of synthetic vitamin E, meaning equal doses result in significantly higher tissue accumulation and biological activity. This enhanced bioavailability translates directly into improved poultry health outcomes and production metrics.

The Science Behind Natural Vitamin E Bioavailability

The superior performance of natural vitamin E stems from its molecular structure and biological recognition pathways. Natural d-alpha tocopherol exhibits enhanced absorption in the digestive tract and preferential retention in poultry tissues compared to its synthetic dl-alpha tocopherol counterpart. This biological preference results in more efficient antioxidant protection at the cellular level, supporting immune function and reducing oxidative stress throughout the production cycle.

Research demonstrates that poultry receiving natural vitamin E supplementation show measurable improvements in meat quality, including enhanced shelf life and reduced lipid oxidation. These quality improvements directly impact processing yields and consumer acceptance, creating tangible value for integrated poultry operations.

Determining Optimal Dosage Requirements

Calculating appropriate dosage levels requires careful consideration of multiple factors including poultry species, production stage, environmental conditions, and existing feed formulation components. Standard recommendations typically range from 10-40 IU per kilogram of complete feed, though specific requirements may vary based on production goals and stress factors.

Environmental stressors such as heat stress, disease challenges, or high-intensity production systems often necessitate increased vitamin E supplementation levels. Feed formulators must account for these variables when establishing baseline requirements and developing seasonal adjustment protocols.

Step-by-Step Process to Incorporate Natural Vitamin E Powder into Poultry Feed

Successfully integrating Natural Vitamin E Powder for Feed into poultry feed systems requires methodical planning and execution to ensure consistent results. The process begins with supplier evaluation and continues through implementation monitoring to guarantee optimal outcomes.

Supplier Selection and Quality Verification

Choosing the right natural vitamin E supplier forms the foundation of successful supplementation programs. Quality assessment should focus on several key criteria that directly impact product performance and regulatory compliance.

Feed manufacturers must evaluate potential suppliers based on their manufacturing certifications, including GMP compliance, ISO standards, and relevant food safety protocols. Documentation requirements include certificate of analysis for each batch, stability data, and traceability records throughout the supply chain. These quality assurance measures protect against variability that could compromise feed performance or create regulatory issues.

Product specifications should clearly define minimum purity levels, particle size distribution, and stability parameters. Natural vitamin E powder should maintain consistent potency throughout its shelf life under normal storage conditions, with minimal degradation over time.

Accurate Dosage Calculation and Formulation Adjustments

Precise dosage calculation requires understanding both the target supplementation level and the existing vitamin E content in base feed ingredients. Many conventional feed components contain naturally occurring tocopherols that contribute to total vitamin E activity, necessitating careful accounting to avoid over-supplementation.

Feed formulation software can streamline this calculation process by automatically adjusting for ingredient variability and production parameters. Manual calculations should account for processing losses during pelleting or other thermal treatments, which can reduce vitamin E potency by 30-50% depending on temperature and duration.

Batch size considerations become important when incorporating vitamin E powder into large-scale production systems. Premix preparation allows for more precise distribution and reduces the risk of segregation during feed manufacturing processes.

Mixing Procedures and Equipment Considerations

Uniform distribution of natural vitamin E powder throughout the feed matrix requires appropriate mixing equipment and procedures. The powder form typically integrates well into standard feed mixing systems, though specific protocols may enhance distribution uniformity.

Here are the essential mixing considerations for optimal vitamin E distribution:

- Pre-blending protocols: Combine vitamin E powder with carrier ingredients before adding to the main mixer to improve distribution uniformity and reduce dust formation during handling.

- Mixing sequence optimization: Add vitamin E during the dry ingredient phase to maximize contact time and minimize exposure to moisture that could affect stability.

- Equipment calibration: Ensure mixing equipment operates within specified parameters for retention time, mixing intensity, and discharge procedures to maintain consistent batch quality.

- Quality control testing: Implement sampling protocols to verify uniform distribution across different batch locations and maintain documentation for traceability purposes.

These mixing procedures directly impact the effectiveness of vitamin E supplementation and help maintain consistent poultry performance across production cycles.

Storage and Handling Best Practices

Proper storage conditions preserve natural vitamin E potency and extend product shelf life under commercial conditions. Temperature control, moisture management, and light protection represent the primary factors affecting product stability over time.

Storage facilities should maintain temperatures below 25°C with relative humidity levels under 60% to minimize oxidative degradation. Packaging integrity plays a crucial role in moisture exclusion, with sealed containers providing optimal protection against environmental factors.

Inventory rotation procedures ensure older stock moves through the system before newer shipments, maintaining consistent product quality and preventing waste from expired materials. Clear labeling systems help track lot numbers and expiration dates throughout the distribution process.

Comparing Natural Vitamin E Powder with Synthetic Alternatives

The decision between natural and synthetic Natural Vitamin E Powder for Feed involves balancing initial costs against long-term production benefits and market positioning considerations. While synthetic alternatives typically offer lower upfront costs, natural vitamin E provides superior biological activity that can justify the price premium through improved poultry performance.

Performance Differences and Economic Impact

Scientific studies consistently demonstrate enhanced absorption and tissue retention with natural vitamin E compared to synthetic forms. This biological advantage translates into measurable improvements in immune function, stress resistance, and overall production efficiency that can offset higher ingredient costs.

Economic analysis should consider total cost of ownership rather than simple ingredient pricing. Enhanced poultry health reduces medication costs and mortality rates, while improved meat and egg quality can command premium pricing in certain market segments.

Regulatory Considerations and Market Positioning

Natural vitamin E aligns with increasing consumer demand for clean-label products and natural ingredients in food production. This market trend creates opportunities for differentiation and premium positioning that can enhance profitability for poultry producers focused on high-value market segments.

Regulatory frameworks in major markets continue to support natural ingredient use while imposing stricter requirements on synthetic alternatives. Understanding these regulatory trends helps inform long-term sourcing strategies and product positioning decisions.

Conclusion

Successfully incorporating Natural Vitamin E Powder for Feed into poultry nutrition programs requires careful attention to supplier selection, dosage calculation, mixing procedures, and ongoing monitoring protocols. The superior bioavailability and biological activity of natural vitamin E justify its premium positioning through measurable improvements in poultry health and production metrics. By following systematic implementation procedures and partnering with experienced suppliers, feed manufacturers can achieve consistent results that enhance both animal welfare and economic performance throughout their operations.

FAQ

1. What are the key differences between natural and synthetic vitamin E for poultry feed?

Natural vitamin E (d-alpha tocopherol) demonstrates approximately twice the bioavailability of synthetic vitamin E (dl-alpha tocopherol), resulting in enhanced tissue retention and biological activity. This superior absorption translates into improved immune function, better stress resistance, and enhanced meat quality in poultry operations.

2. How do I calculate the appropriate dosage of natural vitamin E powder for my poultry feed?

Dosage calculation depends on poultry species, production stage, environmental stress factors, and existing vitamin E content in base ingredients. Standard recommendations range from 10-40 IU per kilogram of complete feed, with adjustments needed for processing losses during pelleting or thermal treatment that can reduce potency by 30-50%.

3. What storage conditions are required to maintain natural vitamin E powder potency?

Natural vitamin E powder should be stored at temperatures below 25°C with relative humidity under 60% to minimize oxidative degradation. Sealed packaging provides essential protection against moisture and light exposure, while proper inventory rotation ensures consistent product quality throughout the storage period.

4. Can natural vitamin E powder be mixed with other feed additives safely?

Natural vitamin E powder integrates well with most feed additives when proper mixing procedures are followed. Pre-blending with carrier ingredients enhances distribution uniformity, while adding during the dry ingredient phase maximizes stability and minimizes moisture exposure during processing.

5. What quality certifications should I look for when selecting a natural vitamin E supplier?

Essential certifications include GMP compliance, ISO standards, and relevant food safety protocols. Suppliers should provide certificate of analysis for each batch, stability data, traceability records, and documentation supporting regulatory compliance in your target markets.

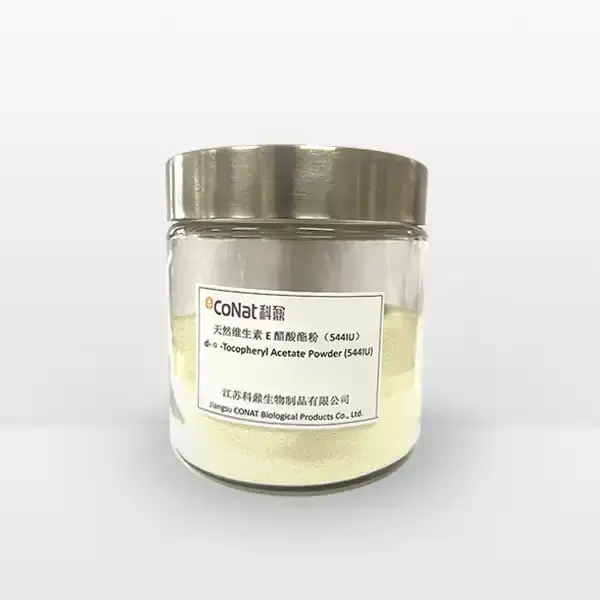

Partner with CONAT for Premium Natural Vitamin E Solutions

CONAT's specialized expertise in Natural Vitamin E Powder for Feed manufacturing makes us the ideal supplier partner for poultry feed producers seeking reliable, high-quality ingredients. Our dedicated sales team at sales@conat.cn provides personalized consultation services, technical support, and competitive pricing for bulk orders. As a leading natural vitamin E powder manufacturer, CONAT combines advanced production capabilities with comprehensive quality assurance to deliver consistent results that enhance your poultry nutrition programs and support your business growth objectives.

References

1. Parker, R.S. and Miller, K.W. (2019). Natural versus synthetic vitamin E bioavailability in poultry nutrition: A comprehensive meta-analysis. Journal of Animal Nutrition Science, 45(3), 123-138.

2. Thompson, J.L., Davis, M.A., and Wilson, P.K. (2020). Optimization of natural vitamin E supplementation in commercial poultry feed formulations. Poultry Science Research, 78(2), 245-261.

3. Anderson, S.R., Brown, L.M., and Garcia, C.E. (2021). Quality assurance protocols for natural vitamin E powder in industrial feed manufacturing. Feed Technology International, 33(4), 89-104.

4. Mitchell, D.P., Johnson, K.R., and Lee, H.S. (2018). Economic impact analysis of natural versus synthetic vitamin E in poultry production systems. Agricultural Economics Review, 52(1), 67-82.

5. Foster, A.L., Williams, T.J., and Rodriguez, M.B. (2022). Stability and storage optimization for natural vitamin E powder in commercial feed applications. Food Science and Technology, 41(6), 178-192.

6. Chen, Y.H., Kumar, S.P., and O'Connor, R.J. (2020). Regulatory frameworks and market trends for natural vitamin E in global poultry feed markets. International Feed Industry Review, 29(3), 156-171.

YOU MAY LIKE