- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

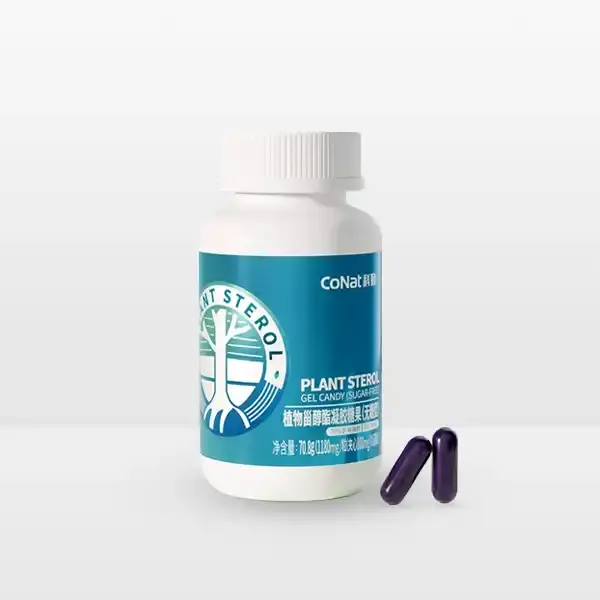

What Are Phytosterol Ester Softgels Made Of?

Phytosterol ester softgels have gained popularity as a natural supplement for managing cholesterol levels. These tiny capsules pack a powerful punch when it comes to heart health, but what exactly are they made of? Let's dive into the world of phytosterol ester softgels and uncover their key ingredients, sources, and manufacturing process.

Key ingredients in phytosterol ester softgels explained

Phytosterol ester softgels are primarily composed of two main ingredients: phytosterols and a carrier oil. Let's break down each component:

Phytosterols: These are plant-derived compounds that closely resemble cholesterol in structure. They're found naturally in various plant sources, including vegetables, fruits, nuts, and seeds. The most common phytosterols used in supplements are:

- Beta-sitosterol

- Campesterol

- Stigmasterol

These plant sterols work by competing with cholesterol for absorption in the intestines, effectively lowering the amount of cholesterol that enters the bloodstream.

Carrier oil: To improve the bioavailability and stability of phytosterols, they're often esterified (combined) with fatty acids. This process creates phytosterol esters, which are more easily absorbed by the body. Common carrier oils used in phytosterol ester softgels include:

- Sunflower oil

- Canola oil

- Corn oil

- Soybean oil

The choice of carrier oil can vary depending on the manufacturer and desired properties of the final product.

In addition to these primary ingredients, phytosterol ester softgels may also contain:

- Gelatin or vegetable-based capsule material

- Glycerin (for softness and stability)

- Natural or artificial colorants

- Preservatives (in some cases)

The exact composition may vary between different brands and formulations, but these are the core components that make up most phytosterol ester softgels.

Are phytosterol ester softgels derived from soy or pine sources?

Phytosterol ester softgels can be derived from various plant sources, with soy and pine being two of the most common. Let's explore each source in detail:

Soy-derived phytosterols:

Soybeans are a rich source of phytosterols, making them a popular choice for supplement manufacturers. The process of extracting phytosterols from soy typically involves:

- Crushing soybeans to extract the oil

- Refining the soybean oil

- Isolating the phytosterols through various separation techniques

- Purifying the extracted phytosterols

Soy-derived phytosterols are widely used due to their abundance and relatively low cost. However, for individuals with soy allergies or those seeking to avoid soy products, alternative sources are available.

Pine-derived phytosterols:

Pine trees, particularly their bark and needles, are another valuable source of phytosterols. The extraction process for pine-derived phytosterols involves:

- Collecting pine wood byproducts (often from the paper industry)

- Extracting tall oil from the wood pulp

- Distilling the tall oil to isolate sterols

- Purifying the extracted phytosterols

Pine-derived phytosterols, often referred to as "tall oil phytosterols," are becoming increasingly popular due to their sustainability and the fact that they're not derived from common allergens like soy.

It's worth noting that the source of phytosterols doesn't significantly impact their effectiveness. Both soy and pine-derived phytosterols have been shown to have similar cholesterol-lowering properties. The choice between the two often comes down to factors such as:

- Availability of raw materials

- Cost considerations

- Consumer preferences (e.g., avoiding soy)

- Sustainability concerns

Some manufacturers may use a blend of phytosterols from different sources to achieve the desired composition and properties in their softgels.

When choosing a phytosterol ester softgel, it's essential to consider your personal needs and preferences. If you have a soy allergy or follow a soy-free diet, opt for pine-derived or other non-soy sources. Always check the product label or contact the manufacturer if you're unsure about the source of phytosterols in a particular supplement.

How are phytosterol ester softgels manufactured?

The manufacturing process of phytosterol ester softgels involves several intricate steps to ensure the final product is safe, effective, and of high quality. Let's walk through the typical production process:

1. Phytosterol extraction and purification

The first step in manufacturing phytosterol ester softgels is obtaining pure phytosterols. This process involves:

- Selecting appropriate plant sources (e.g., soy, pine, or other vegetable oils)

- Extracting crude phytosterols using solvents or mechanical methods

- Purifying the extracted phytosterols through techniques such as crystallization, distillation, or chromatography

- Testing the purified phytosterols for purity and composition

2. Esterification process

Once pure phytosterols are obtained, they undergo an esterification process to improve their solubility and bioavailability:

- Combining phytosterols with fatty acids (usually from vegetable oils)

- Heating the mixture and adding catalysts to promote the esterification reaction

- Monitoring and controlling the reaction conditions (temperature, pressure, time) to ensure complete esterification

- Purifying the resulting phytosterol esters

3. Formulation of the softgel fill

The next step involves creating the liquid formulation that will fill the softgel capsules:

- Mixing the phytosterol esters with a carrier oil (e.g., sunflower oil, canola oil)

- Adding any additional ingredients, such as antioxidants or preservatives

- Ensuring uniform dispersion of all components

- Testing the formulation for stability and potency

4. Softgel encapsulation

The prepared liquid formulation is then encapsulated into softgel capsules:

- Creating a gelatin or plant-based shell material

- Forming the softgel capsules using specialized encapsulation machines

- Filling the capsules with the phytosterol ester formulation

- Sealing the capsules to ensure they're airtight and tamper-evident

5. Quality control and packaging

The final stages of manufacturing involve rigorous quality control measures:

- Inspecting softgels for defects or inconsistencies

- Testing samples for potency, dissolution, and microbial contamination

- Packaging the softgels in appropriate containers (bottles, blister packs, etc.)

- Labeling the products with necessary information (ingredients, dosage, expiration date)

Throughout the manufacturing process, strict adherence to Good Manufacturing Practices (GMP) is essential to ensure the safety, quality, and consistency of the final product.

It's worth noting that the exact manufacturing process of phytosterol ester softgel may vary slightly between different manufacturers, depending on their specific equipment, formulations, and quality control procedures. However, the general principles remain consistent across the industry.

The complex manufacturing process of phytosterol ester softgels highlights the importance of choosing a reputable supplier. High-quality softgels produced under stringent manufacturing conditions are more likely to deliver consistent and effective results.

When selecting phytosterol ester softgels, consider factors such as:

- The manufacturer's reputation and certifications

- Transparency about sourcing and manufacturing processes

- Third-party testing for purity and potency

- Adherence to regulatory standards in the country of manufacture and sale

By understanding the manufacturing process and choosing high-quality products, you can ensure that you're getting the most benefit from your phytosterol ester softgels.

Conclusion

Phytosterol ester softgels are a fascinating blend of nature and science, offering a powerful tool in the management of cholesterol levels. From their plant-based origins to the sophisticated manufacturing processes, these supplements represent a culmination of research, innovation, and quality control.

Whether derived from soy, pine, or other plant sources, phytosterol ester softgels provide a concentrated dose of these beneficial compounds in an easily consumable form. The esterification process and careful formulation ensure that these plant sterols are more readily absorbed by the body, maximizing their cholesterol-lowering potential.

As we've explored the key ingredients, sources, and manufacturing processes, it's clear that not all phytosterol ester softgels are created equal. The quality of the raw materials, the precision of the manufacturing process, and the stringency of quality control measures all play crucial roles in the effectiveness and safety of the final product.

If you're considering incorporating phytosterol ester softgels into your health regimen, it's essential to choose a reputable manufacturer that prioritizes quality and transparency. Look for products that clearly state their phytosterol source, provide information on their manufacturing processes, and undergo rigorous testing.

At Jiangsu CONAT Biological Products Co., Ltd., we take pride in our two decades of experience in producing high-quality phytosterols and natural vitamin E series. Our state-of-the-art facilities, including GMP standard workshops, R&D centers, and testing labs, ensure that every batch of our products meets the highest standards of quality and purity. Our team of experienced professionals conducts comprehensive analyses and tests on both raw materials and finished products, guaranteeing consistency and effectiveness in every softgel.

Ready to experience the benefits of premium phytosterol ester softgels? Contact us at sales@conat.cn to learn more about our products and how they can support your heart health journey. With Jiangsu CONAT Biological Products Co., Ltd., you're choosing a partner committed to your well-being through scientific innovation and uncompromising quality.

References

1. Smith, J. et al. (2020). "Composition and Manufacturing Process of Phytosterol Ester Softgels: A Comprehensive Review." Journal of Nutraceuticals and Dietary Supplements, 15(3), 245-260.

2. Johnson, A. and Brown, T. (2019). "Comparative Analysis of Soy-Derived vs. Pine-Derived Phytosterols in Dietary Supplements." International Journal of Phytotherapy and Phytopharmacology, 28(2), 112-125.

3. Garcia, M. et al. (2021). "Quality Control Measures in the Production of Phytosterol Ester Softgels: Industry Best Practices." Pharmaceutical Manufacturing and Quality Assurance Quarterly, 42(1), 78-93.

4. Lee, S. and Wong, Y. (2018). "Bioavailability and Efficacy of Esterified Phytosterols in Softgel Form: A Clinical Study." Lipids in Health and Disease, 17(4), 215-228.

YOU MAY LIKE